Welcome to marti engineering ag

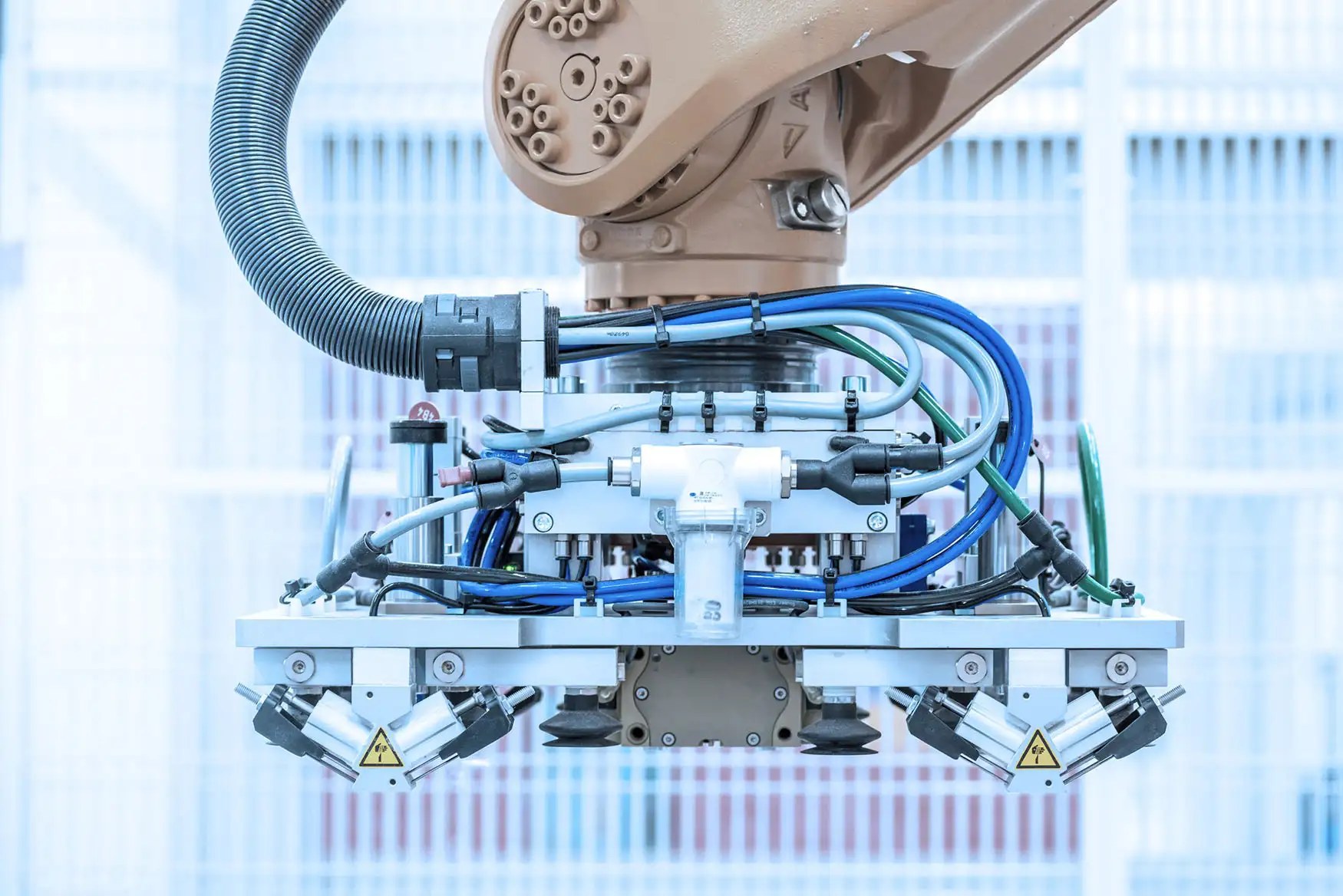

We offer customized automation solutions from a single source. Engineering, manufacturing, mechanical and electrical assembly, PLC programming, commissioning, and maintenance.

Contact options

Get in touch with us

Are you interested in our services and would like a personal consultation with our experts? Send us an email or contact us directly by phone. We look forward to helping you.

Phone

+41 55 647 35 60

office@marti-engineering.ch

End of line testing by marti engineering ag

Whether or not a product meets the final requirements can be determined through our end of line testing systems. As an important part of quality assurance, our systems operate automatically, reliably, and according to the parameters you define in advance – 24/7 and without maintenance.

Automated end of line testing increases testing success

Whether a product fulfills all essential functions after assembly can be verified through quality assurance – but manual testing is complex, time-consuming, costly, and prone to errors depending on scope. In addition, test reports are often incomplete, as they are created by humans. Without suitable systems, reproducible test environments are also lacking, which intensifies the problem. Through reliable end of line testing based on automated test systems, you complete the final step within your production systems and rely on machines that test your products from A to Z. This allows you to perform functional tests on assemblies, household appliances, circuit boards, controls, sensors, battery modules, and many other products.

Advantages of reliable end of line testing

Our end of line testing systems are specifically adapted to industries and companies to meet your requirements. This brings you numerous advantages: For example, ensure that only flawless products are delivered. This reduces returns and associated costs. All test results achieved by our systems are fully traceable. You can review all stored test results later and analyze them with your team as needed. In the long term, this reduces complaints and lowers warranty costs. Since most steps are carried out automatically and handled by integrated test systems, there is no significant manual effort. Overall, through all these measures, you noticeably improve the quality of your finished products without placing additional strain on existing staff or incurring high extra costs.

What can be tested with end of line testing?

Typical test arrangements depend on the type of product and therefore vary by industry. In general, however, end of line testing can determine functionality – for example, to check electrical signals, movement ranges, or torque within mechanical devices. In addition, communication interfaces in various devices can be tested to ensure that the finished product interacts successfully with other interfaces. Furthermore, safety tests, leak tests, and other inspections are possible. If you are unsure, please feel free to contact us, and we will take care of your specific needs in detail. If you require certain test scenarios, we provide customized solutions for successful test runs. Visual inspections using advanced camera technology are also possible.

End of line testing and your time savings

By using end of line testing from marti engineering ag, you benefit from significant time savings compared to manual testing methods. The error rate drops sharply since no subjective evaluation takes place that could contain human mistakes. Desired data collection runs fully automatically and is always complete. While manual spot checks for certain products might take ten to thirty minutes, our automated test systems complete the process within just a few minutes. This saves you a great deal of time while ensuring that every single product is tested – not just random samples.